Lightwave

Technology is fast becoming the primary enabler in the successful delivery of the network infrastructure fueled by the $42.5 billion in Broadband Equity, Access, and Deployment (BEAD) funding and billions of additional dollars available through private, federal, and state grants. And while it remains difficult to predict impact, the consumer demand for next-generation, future-proof fiber networks far outpaces the rate at which telecommunications infrastructure is currently built. Fortunately, the industry is united in the need to reduce network construction time without reducing quality and effectiveness.

Traditional construction management uses longstanding project methodologies that are not designed for today’s network deployments. Further, broadband networks are increasingly more complex and geographically distributed than ever before with coverage and expansion requirements dictated by market demand and the availability of public and private capital. Despite the volume of tasks required, traditional methods rely heavily on manual processes and contribute to the following challenges:

- - Data integrity issues in the absence of a unified, geospatial view of project progress

- - Lack of timely and effective coordination and communication between the field and office

- - Asset and contractor management difficulties

- - Manual, inefficient task scheduling, forecasting, and allocation

- - Paper-based construction packs and manual processes plagued with varying levels of data capture capability and accuracy.

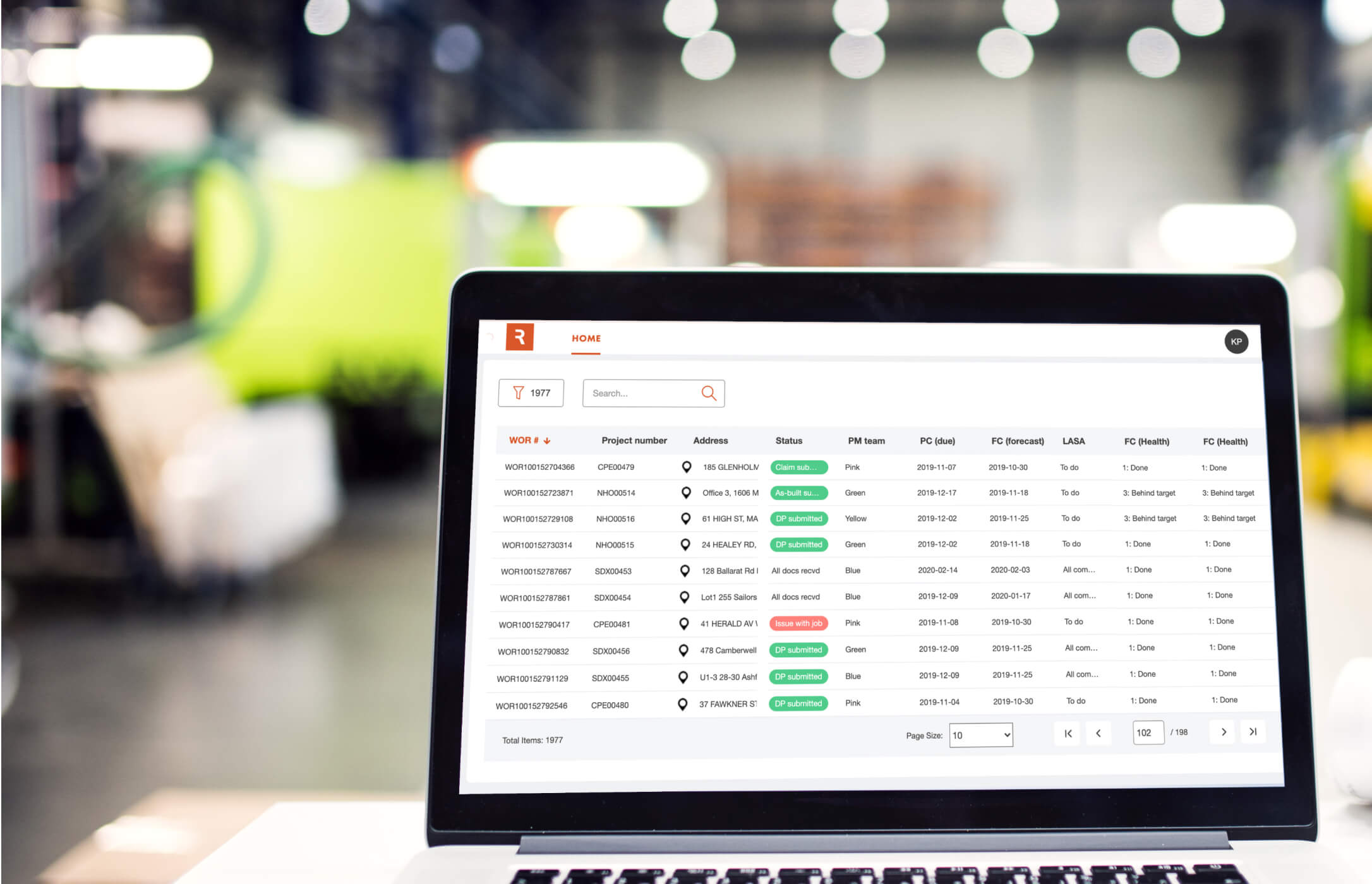

- Moving to an all-digital and geospatial view of construction updated in real-time with production from the field eliminates all these challenges. A single, unified view of the project can be kept in the cloud to keep everyone on the same (virtual) page while maintaining an accurate network record instead of the incipient delays in manually updating progress via paper prints from the field to the office. Construction progress is documented and logged as it occurs, keeping all stakeholders, from planners through to project and network executives, abreast of completions by location.

Digitalization also enables the agile allocation and reallocation of resources as needed. Teams can be instantly dispatched to the next ready construction task - with dependencies considered - instead of having to go back to the office for the next paper-based construction pack. If a resource or asset is not available, crews can be allocated to the next available task without construction delays while waiting on paper, parts, and people to deliver what's next.

Information flow from design to construction and operations is critical

Across the industry, there is a recurring disconnect between feasibility, engineering, and the breakdown of work that's required to optimally construct a quality network. As the design is shared with general contractors and their subcontractors, build requirements and data quality are further diluted.

The quality of construction and change data and its integration into finance, network management, maintenance, and customer relationship management (CRM) systems directly affect how operators can generate revenue and maintain an accurate system of record.

Purpose-built digital construction solutions convert network design into project scope – including work definitions, dependencies material, and resource requirements at the task level – before the project commences. By including downstream system requirements in this scope creation, crews capture accurate and consistent geospatial data as they complete work, enabling a timely operations handover and end-to-end efficiency.

To meet federal and state grant funding requirements, operators must present and adhere to delivery milestones and metrics or risk severe penalties for noncompliance. Successful funding applicants will meet these milestones while effectively tracking construction crew performance, material utilization, quality, and geospatial progress. Early identification of performance issues or at-risk delivery milestones is going to be exceedingly important to operators in the upcoming funding rounds. An all-digital approach enables faster and better build decisions with the ability to track progress in real-time to ensure milestone and public reporting requirements are simplified.

Proven solutions to navigating labor and supply chain constraints

As the industry invests in training the next broadband workforce, operators are feeling increasing pressure to build timelines without resources being readily available. Many broadband operators have recognized the advantages of real-time, cloud-based technology in reducing project management overheads while optimizing available resources, something that’s more critical than ever in this constrained environment.

In Arkansas, Craighead Electric Cooperative Corp. (CECC) found a 75% reduction in project resourcing and administrative overhead using such a digital approach. With the availability of field data and an intuitively designed platform, CECC was able to deploy its outside plant 84% faster than it anticipated during network planning in 2019. Capturing as-built records without needing to manually reconcile data reduced the CECC project management team from 4 to 1.

The highest budget item on a project is labor and we know these constraints are crippling projects. By utilizing real-time data capture in the field, duplicated data processes are eliminated; change management and status reporting are streamlined as well. Management can track planned vs. actual progress and re-forecast every day based on real-time data to enable better workforce management, including identifying which contractors are the most efficient to keep productive teams moving.

Supply chain constraints are still going to challenge the industry in the coming year, and what operators have learned is how critical waste reduction is to manage delivery costs. Because of the reduced waste and improved utilization rates that a technology-enabled approach delivers, operators are turning to tech to optimize materials and ensure visibility of where they are used and by whom. When considering large projects with at least a three-year build forecast, stakeholders previously were not able to track actual vs. planned material usage accurately and, as a result, most rollouts exceeded 10% material waste.

Digital construction technology enables a real-time view of material production data to inform future supply chain requirements. By including required material units by location in construction tasks and matching fiber reels to runs, project and finance teams can track material utilization in real-time and measure waste by crew or contractor. When work is completed correctly the first time with the right materials, operators and contractors typically realize a 2% material waste rate and can nearly halve rework volumes.

Today’s labor constraints will persist as the demand for broadband infrastructure soars over the next five years, but digital and geospatial technology has already exponentially improved how operators manage network builds with less.

GIS is table stakes, geospatial everything is the new benchmark

Considering GIS native technology in every aspect of network design, construction and operations is where the cumulative benefit lies. Broadband service providers increasingly need to plan for and prioritize build areas based on census block and location-based requirements for most federal or state funding programs or the fastest path to revenue generation.

Leveraging geospatial intelligence in the planning process enables a more transparent and predictable construction scope and schedule; it enables identification of problematic areas where construction may be delayed or bottlenecked due to resource constraints or permitting. Once construction commences, GIS data is used to display progress in real-time by documenting completed work or network changes on a map-based view.

Planning for the known unknowns

We know there are going to be obstacles throughout the cycle of a two- to three- or four-year network build. Supply chain and workforce issues continue to be of concern, especially given the ramp of digital infrastructure globally. While suppliers, service providers, and industry associations are seeking ways to meet the increased demand for materials and people power, there are no assurances that their growth curves for increased supply will match it. Add in occasional natural events that have both regional and potentially worldwide consequences to supply, such as hurricanes, floods, and wildfires, and it becomes clear that project managers need to be prepared to consider an agile delivery approach and build solutions.

Digital technology utilization is incredibly important and an enabler to accommodate issues such as supply interruptions, permit delays, or changes in stakeholder priorities. Today’s delay in supply could affect tomorrow’s need to add additional route miles and homes connected because of new funding.

Digital and geospatial construction technology is fast becoming the competitive edge and only way to effectively win bid proposals, deliver projects on time and budget, and hand over an operational network, especially in today’s volatile market. Paper is not the solution, but the problem to meet these challenges, while digital provides the low-to-no-risk solution operators need to accelerate broadband delivery and connectivity where it’s needed most.